PRODUCTS

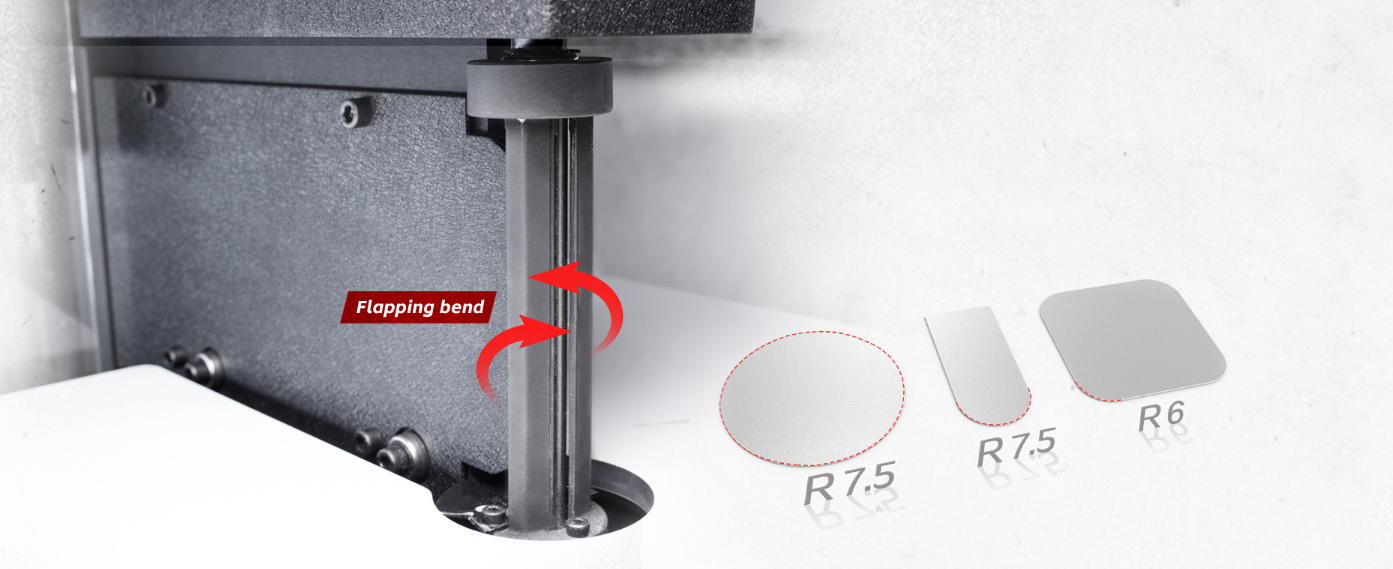

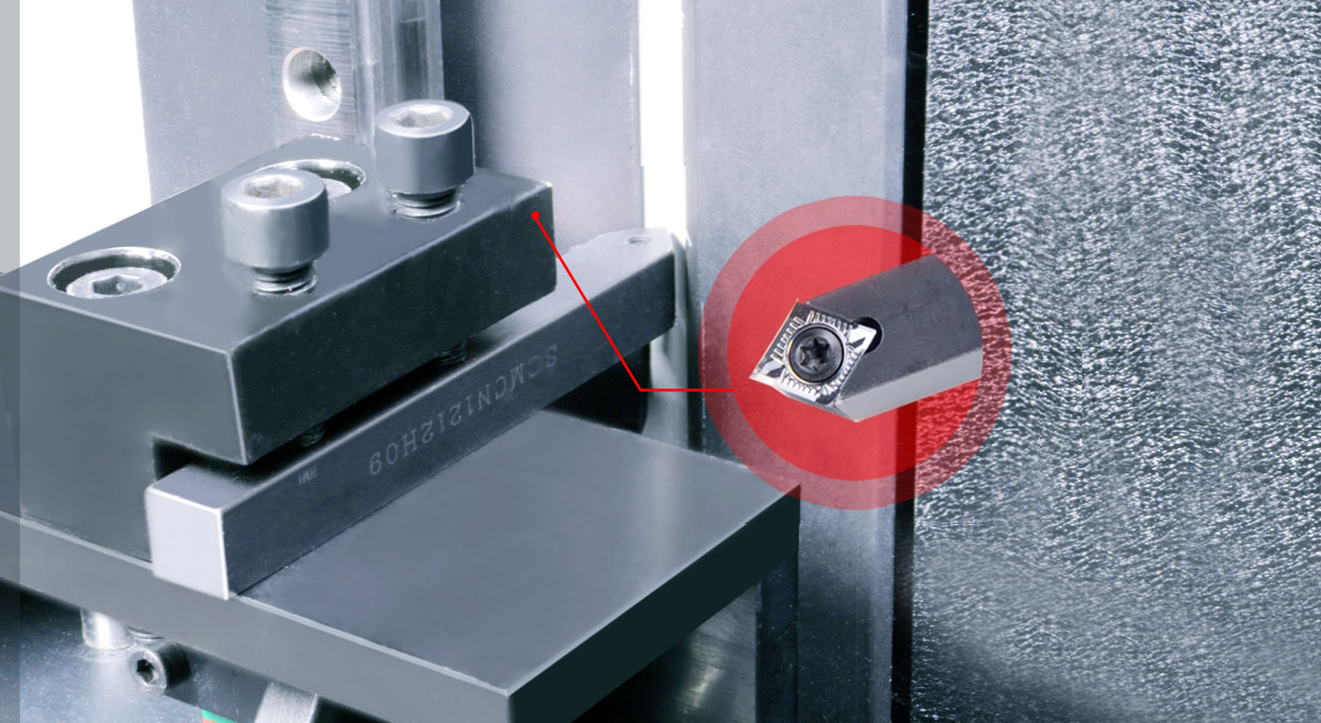

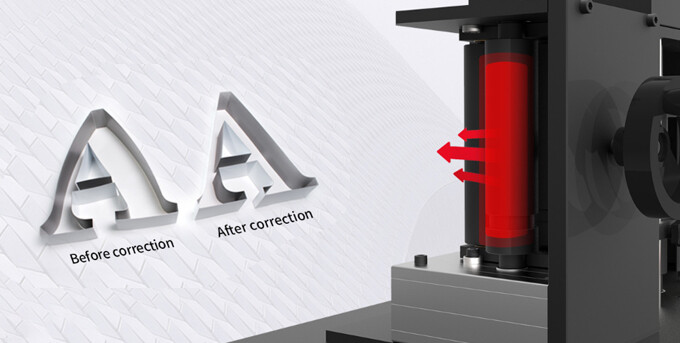

·Alloy planer slotting ·Flapping bending ·Material pre-straightening structure

Rolling Hydraulic Feeding System

Fast, continuous and stable operation, and the material thickness adaptiveNo adjustment is required to change at any time, No marks on the material surface

Rotary Cylinder Cutter Bending

Flapping bending, its bending and forming degree is better than extruded arc bendingThe software has been carefully adjusted and tested, so its bending speed is better than the extruded arc bending according to the actual processing conditions, the software can be used in three bending modes to create more value

4 Core Advantages of JinyuanCNC

The innovative integration of casting structure and intelligent control system enables efficient, stable, and automated production.

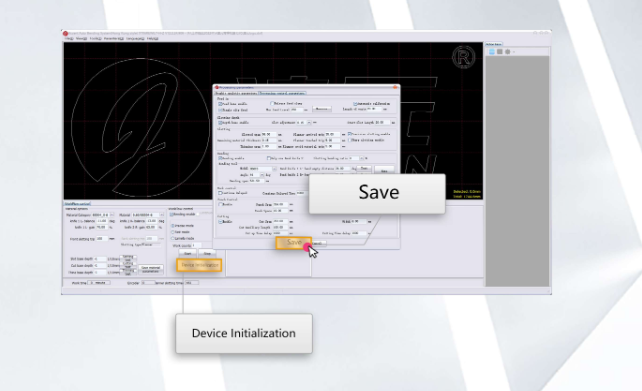

Proprietary Software System

Core components Are Integrally Cast

High-Precision Bending

Globally Tailored Solutions

Product Parameters

JinyuanCNC Channel Letter Bending Machine,Factory Price

15 years experience, professional selection guidanceDirect factory prices, high cost-performance ratio

Professional after-sales team, 24/7 service

Free technical solution

Sample test support

Factory visit support

Machine installation and training

Remote service support

Become our global distributor

Technical parameters

Product Recommendations

Send Us Your Inquiry

Inquire Now

Your comprehensive manufacturing solutions partner, we empower global enterprises to optimize production efficiency and drive business growth through our self-developed CNC equipment, proprietary software, and full-chain services.