PRODUCTS

Advantage 1: Seiko Standard

The edge of the panel has a tiny R Angle, which does not produce bevel chamfering and does not break the letters

Advantage2: Stable Effect, High Yield

The letters shell is placed on the plane, and the grinding head rotates around the fixed pint to carry out translations operation at all angles.

Advantage3: Improve The Efficiency And Reduce Cost

According to the actual use calculation of several users, 0 basic grinding workers only need 20 man-hours to start the work, 7 days or so can be more skilled work, 30 days to carry out efficient grinding work

Advantage4: Safety Guarantee

As the grinding head rotates at a fixed point and cannot be moved, the word shell is placed on the table, and the hand only moves the word shell in directions, so there will be no accident such as grinder injury

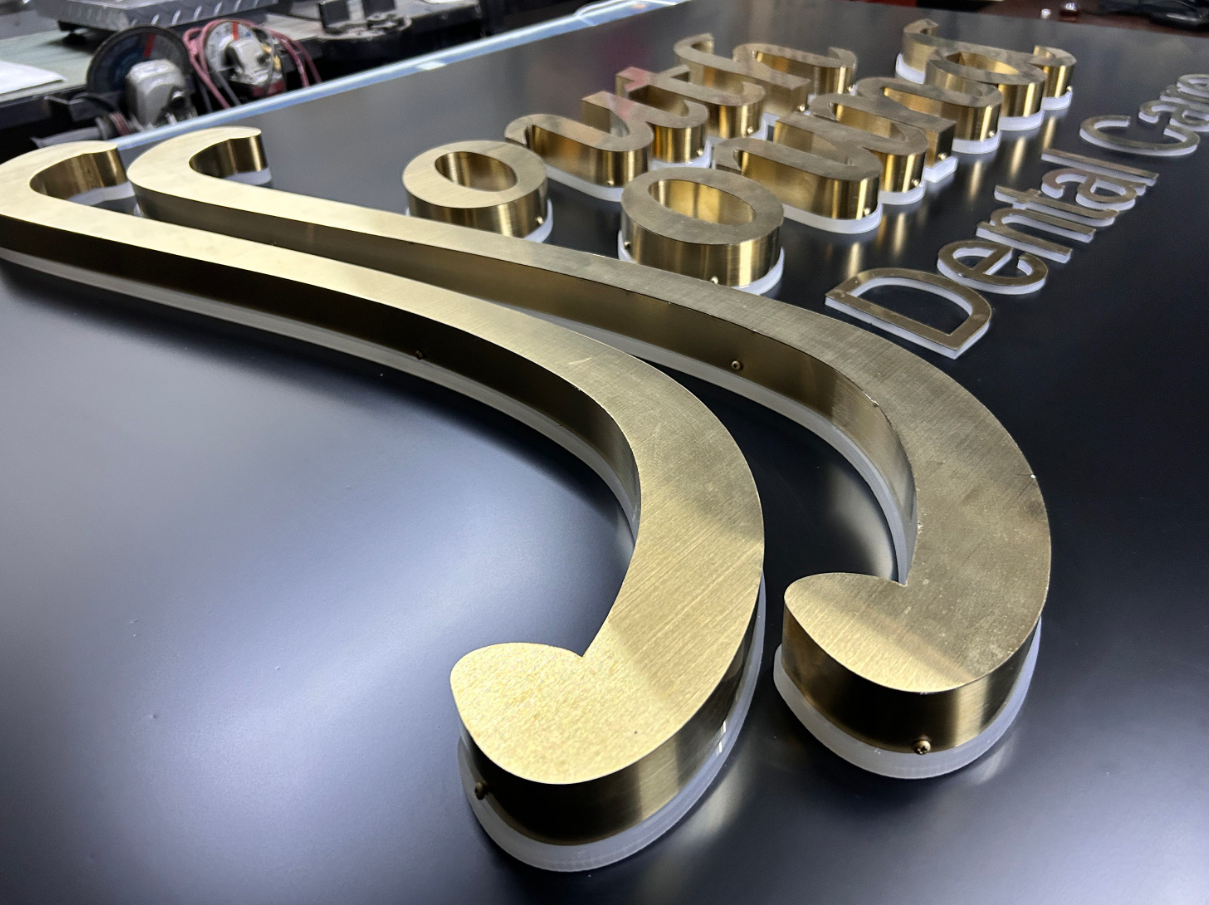

Sample application

4 Core Advantages of JinyuanCNC

The innovative integration of casting structure and intelligent control system enables efficient, stable, and automated production.

Proprietary Software System

Core components Are Integrally Cast

High-Precision Bending

Globally Tailored Solutions

Product Features

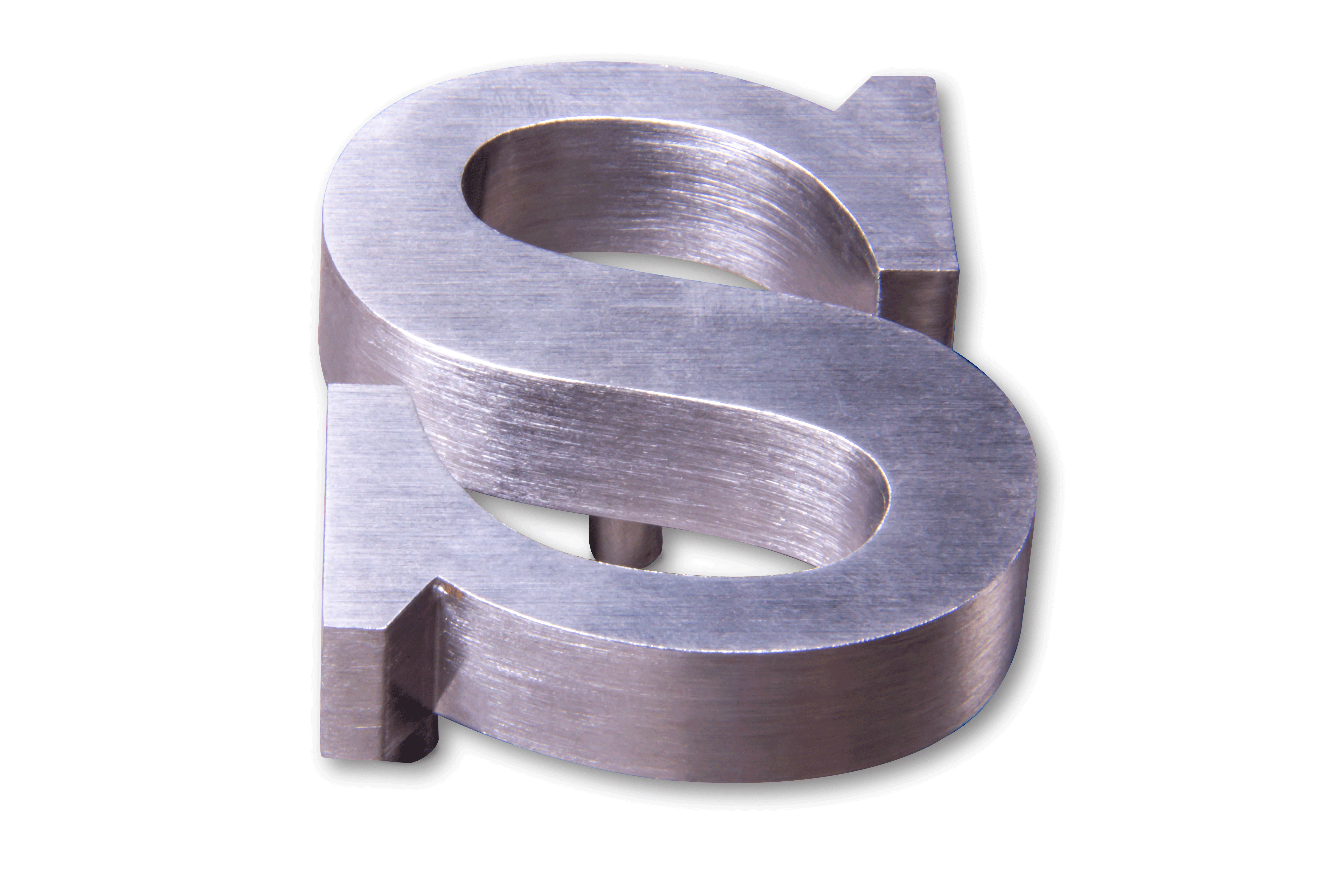

Advantage 1: Seiko Standard

The edge of the panel has a tiny R Angle, which does not produce bevel chamfering and does not break the letters

For the word shell polished by hand with Angle grinder.Obvious chamfered shape appears at the border position of the panel and the sideband, destroying from and finished product effect

Advantage 2: Stable Effect, High Yield

The letters shell is placed on the plane, and the grinding head rotates around the fixed pint to carry out translations operation at all angles.The letters shell gets stable support, the polishing effect is stable and outstanding , the yield is very high

When holding the Angle grinder in hand,the hand cannot be effectively supported because it is suspended in the air.It is easy to cause uneven damage to the word shell when grinding, resulting in a higher rejection rate

Advantage 3: Improve The Efficiency And Reduce Cost

According to the actual use calculation of several users, 0 basic grinding workers only need 20 man-hours to start the work, 7 days or so can be more skilled work, 30 days to carry out efficient grinding work

It only takes 30 days for basic staff to work efficiently from the beginning, and the polishing efficiency has been increased by 30% compared with that of finishing in the polishing process, and by 40% compared with that of finishing in the polishing process.In addition, the labor cost has been reduced and the work efficiency has been significantly improved

Advantage 4: Safety Guarantee

As the grinding head rotates at a fixed point and cannot be moved, the word shell is placed on the table, and the hand only moves the word shell in directions, so there will be no accident such as grinder injury

JinyuanCNC Channel Letter Bending Machine,Factory Price

15 years experience, professional selection guidanceDirect factory prices, high cost-performance ratio

Professional after-sales team, 24/7 service

Free technical solution

Sample test support

Factory visit support

Machine installation and training

Remote service support

Become our global distributor

Technical parameters

Product Recommendations

Send Us Your Inquiry

Inquire Now

Your comprehensive manufacturing solutions partner, we empower global enterprises to optimize production efficiency and drive business growth through our self-developed CNC equipment, proprietary software, and full-chain services.